Intoduction of the DTF technology

What is DTF?

DTF stands for the ’direct to film’ expression that refers a printing method, that the ink is printed directly on the transfer film. The DTF technology became popular and widespred a few years ago, around 2020. DTF revolutionized the personalization industry, as it has numerous advantages compared to the other existing embleming technologies.

The DTF printing process is very fast and easy, the printer prints directly to the transfer film with CMYK + White color ink, after that the hot melt powder have to be shake on the prints as this will fix the design. The production process ends with the drying of the powder, this is necessary because as the powder melts it picks up the pigments, with that the prints get a nice, flexible form and became ready to use.

The usage of these DTF prints and stickers require an iron or a heat press machine and a scicross. We have to cut the printed designs, place it on the material where we want to place it and press it up with the heat press machine for 15 seconds at 160°C. After this, the transfer foil can be pulled off and we highly recommend to do a fixing press for 6-8 seconds just to ensure that the DTf print stuck perfectly.

The main advantages of DTF technology

The main advantages of this DTF technology is that these stickers can be used not only white and coloured but also on dark and black textiles thanks to the white layer. Moreover, even only white colored prints can be made with this technology. The other main advantage that these prints perfectly picks up the texture of the materials, so compared to the flex foil technology the thickness of these prints are really thin, almost imperceptible. These prints are really high-quality, vivid and bright colored and also very detailed designs can be made with this DTF technology as small dots, thin lines and small texts does not mean any challenge. From the user point of view there are some other benefits, as the prodcution costs is really low as there is no need for pre-treatment and no extra tools are needed for different designs. At this point we think it is important to mention that beside the lot of advantages of this DTF technology, there are some hardships that can occur. One problem that can occur is the grey color, as other digital printing technologies, DTF also uses CMYK mode as mentioned before, not Panthone. It is quite hard to produce the desired grey color, because every machines prints a slightly differently that has a huge effect in the case of grey color. To solve this issue, we highly recommend to always print tests before any settlement that includes grey colored prints. Regardless of this issue this technology provides a cheap and reasonable solution in the personalization industry for everyone.

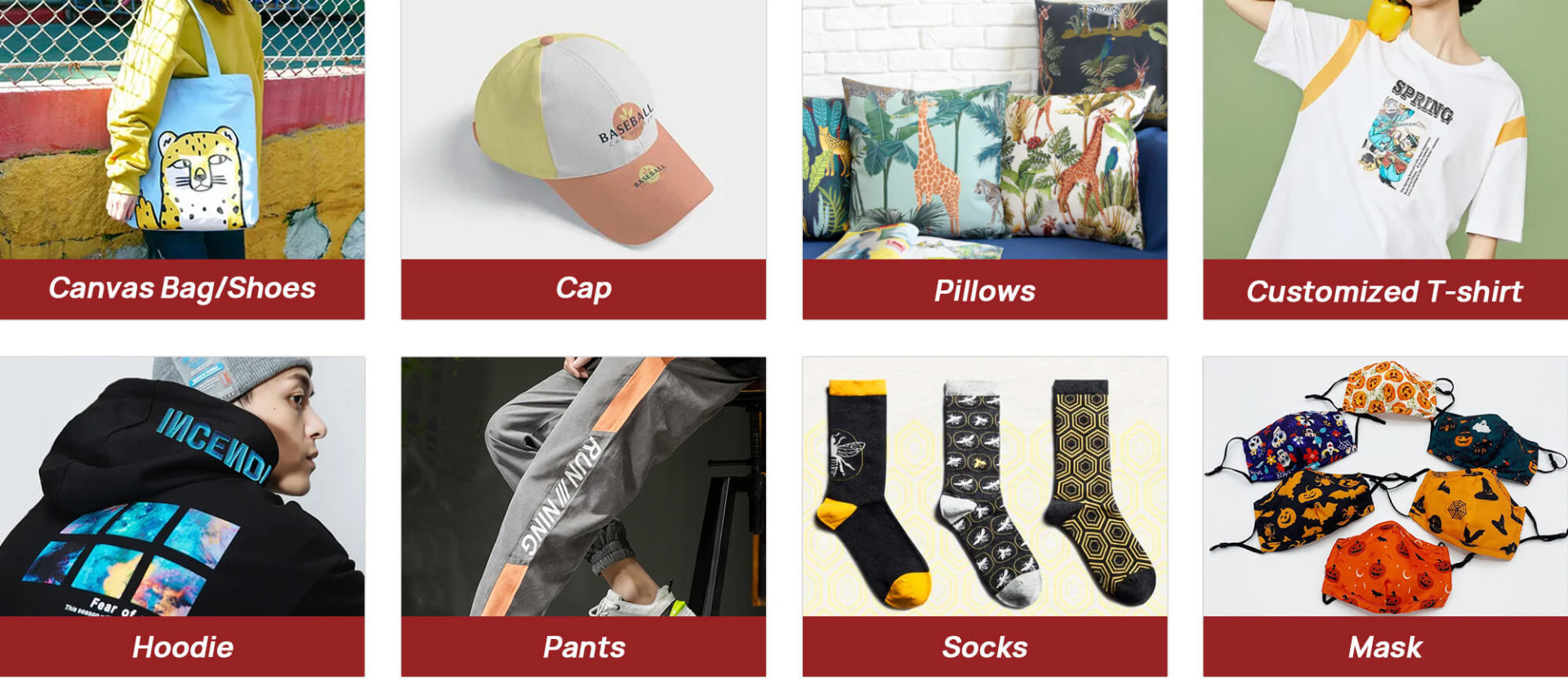

These DTF prints not only easy to use, but also it has a wide range of application. DTF prints firstly can be used on flexible, textile products but there are some other products that can be personalize with DTF. From the basic T-shirts, shirts, jumpers, hoodies, trousers, hats, coats, joggers, scarfs, ties, socks and even umbrellas can be used for DTF. Beside these there are some products that was problematic to emblem before the DTF technology, such as rain coats or sport apparels. Now, with this technology the problem disappeared as the technology has made an easy way to emblem these products too. Some examples of other products that DTF can be used are envelopes, wooden boards, bags and paper bags.

Which printer will be the best one for you?

To help you find out which DTF printer would be the most suitable for your business we created this little table to give you an overview. In general the size and the printing speed of the printer are the main parameters that determines which will be the most suitable. For those companies who seeks for a half way solution between the commercial and industrial printers and may have a lack of space in their office, we reccomend the SEN-A331 30cm wide compact DTF Printer. It provides a roll-to-roll soultion, with high effectiveness and efficiency, the printer is easy to install and highly userfriendly.

For those who are looking for an industrial printer we recomment the PRO-A600 DTF printer or the EVO-A600, these both are 60cm wide roll-to-roll DTF printers with powder system. The main advantage of these DTF printer is the printing speed that can be up to 12 m2/h.

If you would like to use the DTF technology and its various advantages but don’t want to buy a printer we recommend you to order ready-to-use prints from a company that provides printing services. Here we would like to suggest one of our partner’s website: www.dtfprinting.eu .

Overall, we can say that DTF technology brought a new era in the personalization industry. This technology not only found a solution to numerous previous problems but also made personalization accessible and affordable for entrepreneurs and companies. Not only the technology itself is amazing, but the printers that made it enjoyable. We are proudly one of the Hanrun Paper Co. Ltd. brand ambadassors in Central-Europe, in our product portfoilo every business can find the most suitable DTF printer for them. All these DTF printers and materials represents very high quality, good price-performance ratio, user-friendly and we provide our partners with a professional, technical service.

As we have more than 2 year experience in the DTF printing, sold more than 100 DTF printers we have plenty experience, knowledge, know hows that we are ready to share with our partners. We tried and tested lot of different DTF printers, because we always seek the best quality that we can recommend anyone with out wholeheart. If you have any question that remained unanswered do not hesitate to contact us, we will happly find you the best printing solution!